Shop Drawings & CNC Documentation

Factory-Ready Shop Drawings & CNC Outputs for Modular & Panelized Production

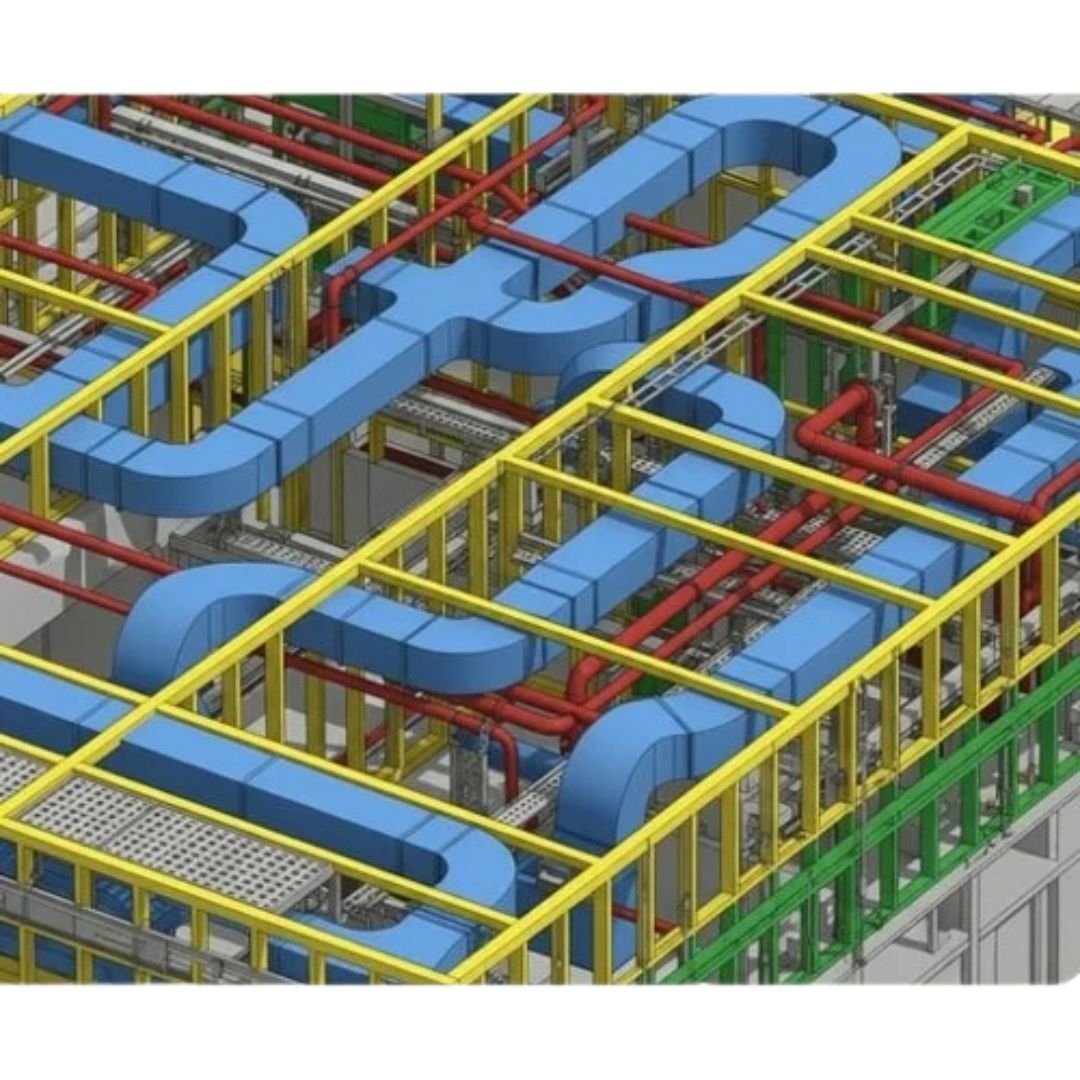

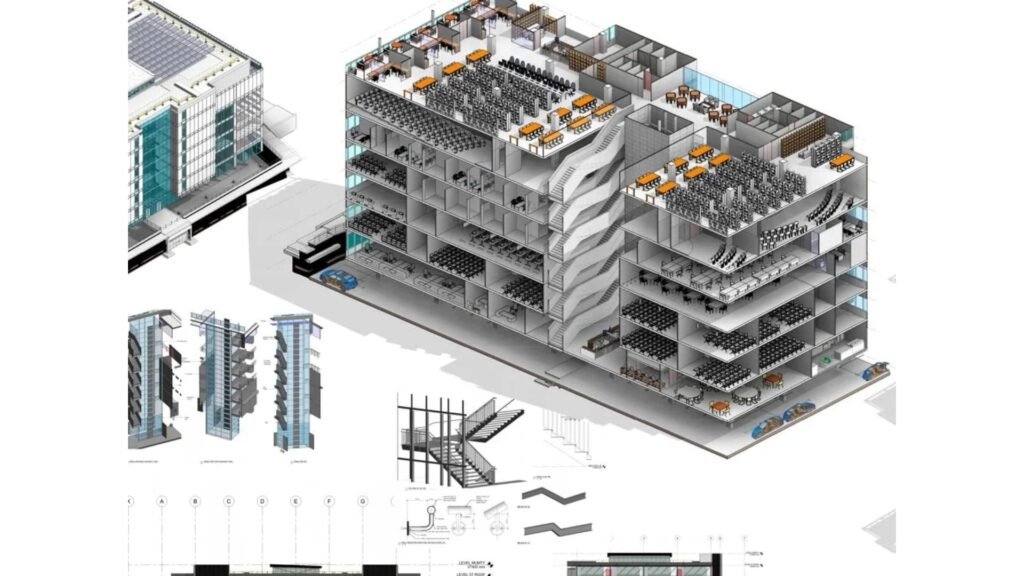

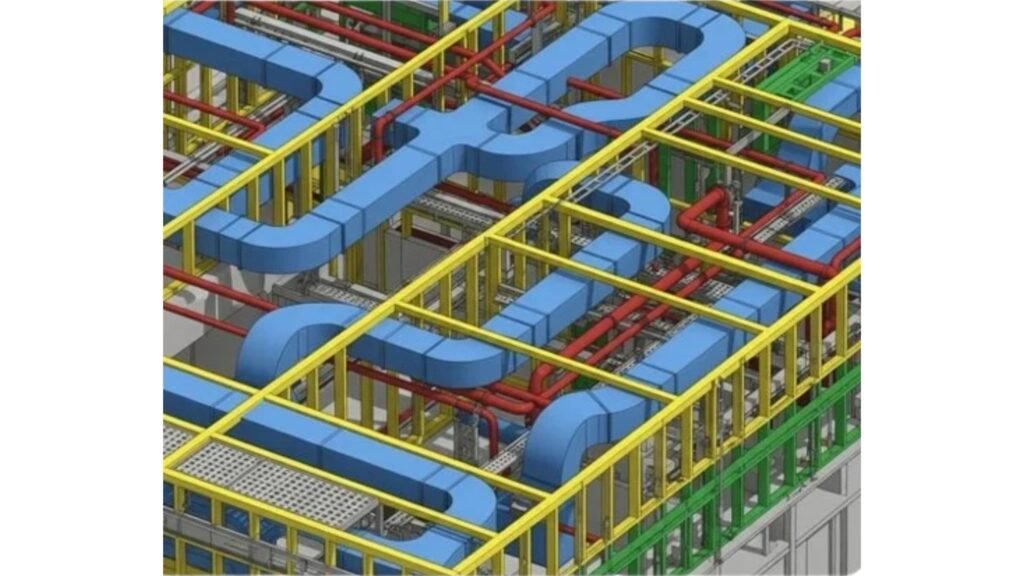

Our dedicated BIM teams deliver highly detailed fabrication documents, including module shop drawings, panel schedules, framing diagrams, CNC-ready breakdowns, cut lists, and assembly instructions.

Each output is developed to match your factory’s production method, tooling, tolerances, and assembly workflow — ensuring your modules and panels can be built accurately and efficiently.

From early prototypes to full production packages, we create documentation optimized for both manual and automated fabrication environments.

Achievements Through The Years

You will find yourself working in a true partnership that results in an incredible experience, and an end product that is the best.

Happy Clients

Executed Projects

Countries

Year Experience

Built for Modular Factories, Panel Shops & Automated CNC Production

Fabrication drawings are the backbone of modular manufacturing.

Our shop drawing packages are built directly from coordinated BIM models to ensure each panel, module, framing member, and MEP rough-in is fabricated exactly as intended — without rework or field correction.

Your dedicated BIM team produces highly detailed shop drawings tailored to your factory workflow, including panel numbering systems, module assembly diagrams, CNC files, and material breakdowns.

During initial projects, we refine templates and documentation standards until everything aligns perfectly with your manufacturing system.

Our shop drawings and CNC data allow your team to move from BIM model → production with confidence.

Shop Drawing & CNC Documentation Capabilities

Panel Shop Drawings

Module Shop Drawings

CNC-Compatible Panel Breakdowns

Structural Framing Diagrams

MEP Rough-In Documentation

Assembly & Installation Diagrams

Material Lists & Cut Schedules

Quality-Controlled Documentation Standards

Why Manufacturers Trust Our Shop Drawings

Dedicated Fabrication BIM Team

Full-time specialists producing consistent, factory-ready outputs.

CNC-Optimized Documentation

All drawings and breakdowns prepared for automated tools.

Alignment With Your Factory Standards

Templates and workflows built around your exact production method.

Reduced Factory Rework

Clash-free, ready-to-build drawings approved by QC.

Scalable Team Model

We hire & train additional staff as your production grows.

How We Onboard & Work With Your Company

Initial Consultation & Requirements Gathering

We begin with a detailed meeting to understand your company’s standards, project requirements, and workflow expectations. We then prepare a structured question list to clarify every detail

Workflow Mapping & Checklist Creation

Based on your requirements, we create an initial workflow map, modeling checklist, and documentation template tailored specifically to your company. This becomes the operational base for your dedicated BIM team.

Full Workflow Integration & Long-Term Execution

Once aligned, your dedicated BIM team follows the finalized workflow consistently across all future projects. Updates are made only when required to support improved efficiency or company changes.

Team Scaling & Training

As your business grows, we hire, train, and onboard additional BIM specialists exclusively for your company—ensuring stable, scalable capacity without internal hiring pressure.

Frequently Asked Questions

Yes. Your dedicated BIM team follows your templates, naming conventions, manufacturing standards, and internal processes from day one.

We also refine and align the workflow during the first few projects to ensure complete compatibility with your system.

Yes. As your workload increases, we hire, train, and onboard new BIM specialists exclusively for your company.

This allows your production capacity to grow without handling recruitment or training internally.

We support volumetric modular buildings, panelized systems, hybrid modular structures, prefab steel/timber units, and modular MEP assemblies.

From conceptual layouts to fully detailed fabrication models, your team can handle all stages of BIM development.

We apply a structured QC system that includes:

Multi-discipline coordination (Arch/Struct/MEP)

Clash detection

Template and standard compliance

Internal review cycles before delivery

This ensures precise, fabrication-ready BIM outputs.

Absolutely. Your dedicated BIM team communicates directly with your internal teams through your preferred channels—Slack, Teams, Zoom, or BIM360—and integrates seamlessly into your engineering and production workflow.

Most engagements begin within 5–10 business days, depending on the complexity of your workflow and the number of team members required.

The onboarding phase includes meetings, requirements gathering, workflow alignment, and checklist creation.

Recent Modular BIM Work Completed by Our Dedicated Team

Explore fabrication-ready BIM models, modular assemblies, panelized systems, and MEP prefabrication work completed by our dedicated BIM team. These projects show how PBD supports modular builders with accurate Revit models, shop drawings, and coordinated BIM documentation across the USA, UK, and Europe.

Ready to Build Your Dedicated BIM Team?

We help modular and offsite construction companies scale their BIM capacity with full-time, dedicated teams managed and trained by PBD. If you’re ready to strengthen your production workflow, let’s discuss how our team can support your growth

Our Special Clients

Let’s Build Your Dedicated BIM Team!

if you’re looking for reliable BIM capacity for modular or offsite construction, our team is ready to support you. Contact us to discuss how a dedicated BIM team—trained, managed, and scaled by PBD—can integrate into your workflow and support your production needs.

Our Phone

+1 818 741 3899

Our MailBox

info@probuildingdesigner.com

Our Address:

15442 VENTURA BLVD., STE 201-663 SHERMAN OAKS, CALIFORNIA 91403